What factors contribute to the cost of Printed velvet laminate fabric?

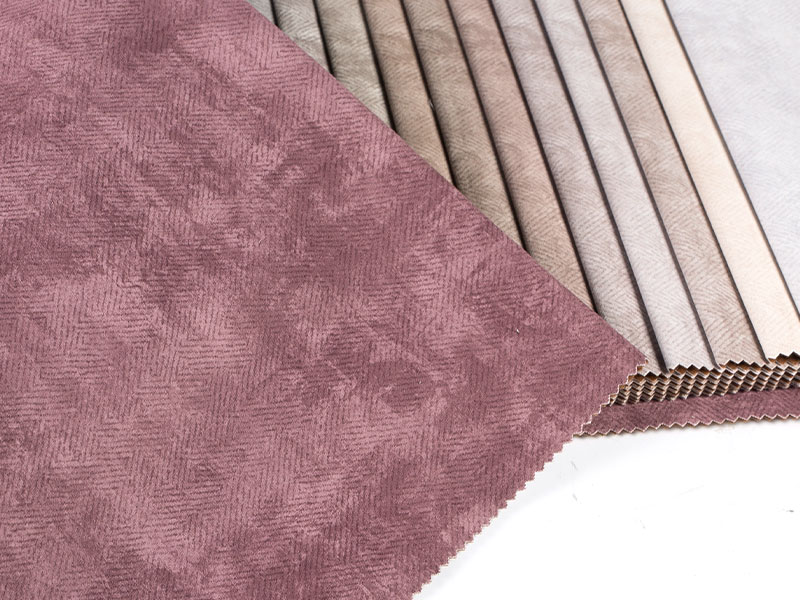

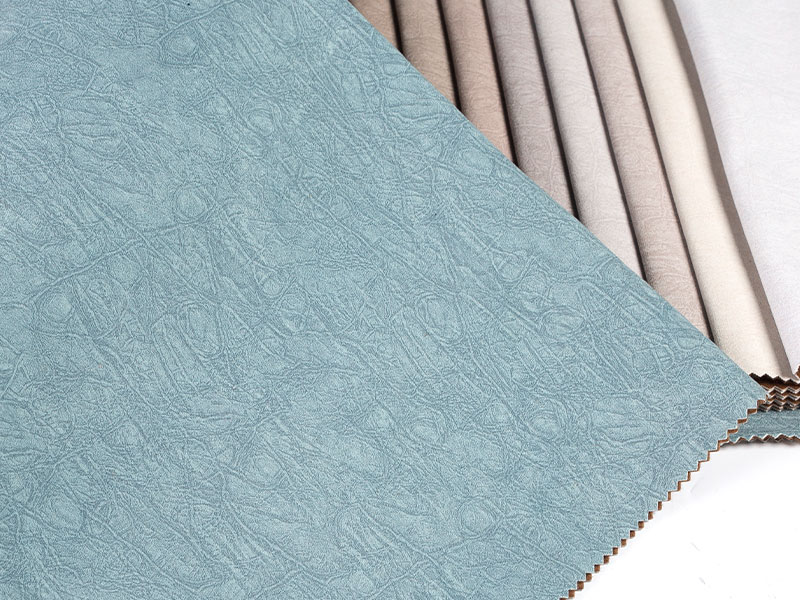

The cost of

printed velvet laminate fabric can vary based on several factors, reflecting the complexities involved in the production and quality of the final product. Here are key factors that contribute to the cost:

Base Fabric Quality:The quality of the base velvet fabric is a significant cost factor. High-quality fabrics, often made from premium fibers like silk or high-grade synthetic materials, can be more expensive.

Lamination Process:The lamination process involves applying a layer of film or coating to the fabric. The type and quality of lamination, including the materials used, can impact the cost. Advanced lamination techniques or specialty coatings may contribute to higher costs.

Printing Technology:The printing method used can affect the cost. Advanced printing technologies, such as digital printing, may be more expensive than traditional methods. Digital printing allows for intricate designs, high color precision, and flexibility but requires specialized equipment.

Design Complexity:The complexity of the printed design influences the cost. Elaborate and intricate patterns, as well as designs with multiple colors, may require more time and resources during the printing process, contributing to higher costs.

Color Quality and Precision:The quality and precision of colors in the printed design can affect the cost. High-resolution and color-accurate printing may involve additional steps in the production process, contributing to increased costs.

Dye Quality:The quality of the dyes used in the printing process is a critical factor. High-quality, colorfast dyes can enhance the vibrancy and longevity of the printed design but may be more expensive.

Customization:Customization options, such as the ability to print unique designs or colors, can increase costs. Custom orders often involve additional setup and processing steps to meet specific customer requirements.

Fabric Width and Weight:The width and weight of the fabric can impact costs. Wider fabrics or those with a heavier weight may require more materials and resources, contributing to higher production costs.

Licensing and Design Fees:If the printed design involves licensed or proprietary artwork, there may be additional fees associated with using those designs. Exclusive or custom designs may also incur extra costs.

Quality Control Measures:Stringent quality control processes add to the overall cost. Manufacturers investing in quality assurance measures to ensure consistent color, pattern, and overall fabric quality may charge higher prices.

Environmental Considerations:Sustainable and eco-friendly production processes may involve additional costs. Certifications for environmentally friendly practices or the use of sustainable materials can impact the overall cost of production.

Market Demand and Supply:Market conditions, including demand and supply dynamics, can influence prices. Limited availability of a particular design or high demand for printed velvet laminate fabric may lead to higher prices.

Considering these factors collectively provides a comprehensive understanding of why the cost of printed velvet laminate fabric can vary, and it allows consumers and businesses to make informed decisions based on their specific needs and budget constraints.

How does sustainability play a role in the production of Printed velvet laminate fabric?

Sustainability in the production of

printed velvet laminate fabric involves incorporating environmentally friendly practices and materials throughout the manufacturing process. Here are ways in which sustainability can play a role in the production of this type of fabric:

Eco-Friendly Fibers:Choosing sustainable and responsibly sourced fibers for the base velvet fabric is a key consideration. Natural fibers like organic cotton or bamboo, or recycled synthetic fibers, are options that reduce the environmental impact.

Environmentally Friendly Dyes:Opting for low-impact or water-based dyes in the printing process minimizes the use of harmful chemicals. These dyes are designed to have lower environmental impact, using fewer water resources and producing less wastewater.

Digital Printing Technology:Digital printing is generally considered more sustainable than traditional printing methods. It often requires fewer resources, produces less waste, and allows for more precise color application, reducing the need for excessive dye usage.

Water and Energy Efficiency:Implementing processes that enhance water and energy efficiency in both printing and lamination stages contributes to sustainability. Technologies that reduce water consumption and energy use help minimize the environmental footprint.

Recyclable or Biodegradable Laminates:Using laminates that are recyclable or biodegradable contributes to the sustainability of the final product. This choice helps reduce the environmental impact when the fabric reaches the end of its life cycle.

Reduced Chemical Use:Minimizing the use of harmful chemicals, such as certain adhesives or solvents in the lamination process, aligns with sustainable practices. This reduces the potential negative impact on both the environment and workers.

Waste Reduction:Implementing measures to reduce waste at various stages of production is crucial for sustainability. This includes optimizing pattern layouts during printing to minimize fabric waste and recycling or repurposing production scraps.

Certifications and Standards:Adhering to recognized sustainability certifications and standards, such as Global Organic Textile Standard (GOTS), OEKO-TEX, or others, demonstrates a commitment to environmentally responsible practices and materials.

Closed-Loop Systems:Implementing closed-loop systems for water and chemicals helps minimize the release of pollutants into the environment. Closed-loop systems are designed to recirculate and reuse water and chemicals in the production process.

Supply Chain Transparency:Providing transparency in the supply chain, from raw material sourcing to the final product, allows consumers to make informed choices and supports sustainable practices throughout the entire lifecycle of the fabric.

End-of-Life Considerations:Considering the fabric's end-of-life phase is an essential aspect of sustainability. Designing products that are recyclable or biodegradable facilitates responsible disposal and reduces the overall environmental impact.

Renewable Energy Sources:Utilizing renewable energy sources, such as solar or wind power, for manufacturing processes contributes to a lower carbon footprint and aligns with sustainable practices.

By integrating these sustainable practices into the production of printed velvet laminate fabric, manufacturers can reduce the environmental impact of their operations, meet growing consumer demands for eco-friendly products, and contribute to the broader goal of creating a more sustainable and responsible textile industry.

Language

Language  English

English 中文简体

中文简体 عربى

عربى