What distinguishes printed emboss lamination velvet fabric from other types of velvet?

Printed emboss lamination velvet fabric stands out from other types of velvet due to its unique combination of features, including the incorporation of printed designs, embossed patterns, and a lamination layer. Here are the distinguishing characteristics of printed emboss lamination velvet fabric:

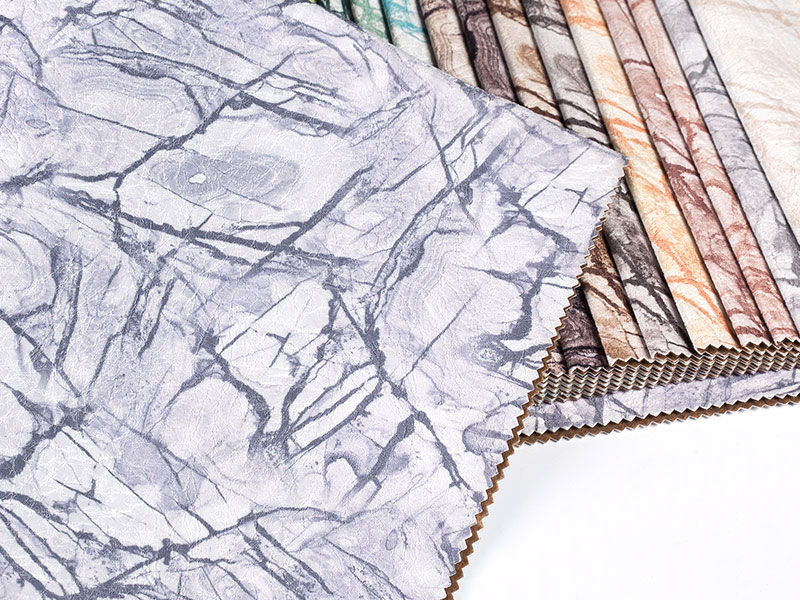

Printed Designs:

Visual Appeal: One of the key features is the ability to incorporate printed designs onto the velvet fabric. This allows for a wide range of patterns, motifs, and colors, adding visual interest and customization options.

Embossed Patterns:

Textural Depth: The fabric undergoes an embossing process, which creates raised patterns on the surface. This textural depth adds a tactile element to the fabric, enhancing its overall aesthetic appeal.

Lamination Layer:

Protective Coating: Lamination involves applying a protective layer to the fabric. This layer serves to enhance the durability of the fabric by providing resistance against wear, stains, and fading. It also adds a subtle sheen to the surface.

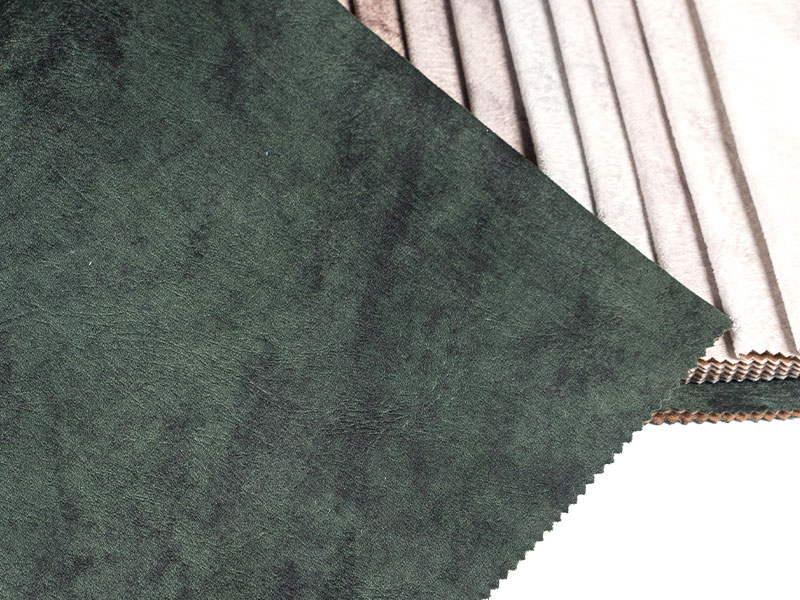

Unique Texture:

Combination of Softness and Texture: The combination of velvet's inherent softness with embossed patterns and the protective lamination layer creates a fabric with a unique texture. It is both visually and tactilely appealing.

Versatility:

Applications in Various Industries: Printed emboss lamination velvet fabric is versatile and finds applications in diverse industries, including fashion, upholstery, and home decor, due to its distinctive appearance and texture.

Customization Options:

Tailored Designs: Users have the option to customize the fabric with specific designs, patterns, and colors according to their preferences. This customization feature makes it suitable for a range of creative applications.

Enhanced Durability:

Wear and Stain Resistance: The lamination layer not only enhances visual appeal but also contributes to the fabric's durability. It makes the fabric more resistant to wear, stains, and potential damage, making it suitable for various uses.

Modern Aesthetic:

Contemporary Designs: The combination of printing and embossing often lends itself well to modern and contemporary design aesthetics. It allows for the creation of visually striking and trendy patterns.

Intricate Detailing:

Detailed Patterns: The embossing process enables the creation of intricate and well-defined patterns. This level of detail contributes to the fabric's overall sophistication.

Textured Light Reflection:

Dynamic Visual Effect: The embossed patterns on the velvet fabric can interact with light in interesting ways, creating a dynamic visual effect that adds depth and dimension to the material.

Creative Applications:

Fashion and Decor: The fabric is well-suited for applications where both visual and tactile appeal are important, making it a popular choice for fashion items, upholstery, and decorative elements.

In summary, printed emboss lamination velvet fabric distinguishes itself by seamlessly combining the softness of velvet with printed designs, embossed textures, and a protective lamination layer. This results in a fabric that is not only visually appealing but also durable and versatile for a range of creative applications.

What maintenance considerations should users be aware of for printed emboss lamination velvet fabric?

General Care:

Regular Dusting:Dust the fabric regularly using a soft brush or a vacuum cleaner with a soft brush attachment. This helps prevent the accumulation of dirt and dust on the surface.

Gentle Cleaning:Clean the fabric using a mild detergent or upholstery cleaner. Follow the manufacturer's instructions for cleaning, and avoid using harsh chemicals that could damage the printed or laminated surface.

Prompt Stain Removal:Attend to spills or stains promptly. Blot the stain with a clean, dry cloth or a paper towel. Avoid rubbing, as it may push the stain deeper into the fabric.

Avoid Direct Sunlight:Minimize exposure to direct sunlight, as prolonged exposure can lead to fading of the printed and laminated areas. Use curtains or blinds to protect the fabric from intense sunlight.

Rotate and Rearrange:If possible, rotate or rearrange furniture upholstered with printed emboss lamination velvet fabric. This helps distribute wear more evenly across the fabric.

Specific Care for Laminated Velvet Fabric:

Avoid Harsh Cleaning Agents:Use mild cleaning agents specifically recommended for laminated fabrics. Harsh chemicals can damage the lamination layer and affect the overall appearance.

Prevent Scratching:Avoid abrasive cleaning tools or materials that could scratch or damage the lamination layer. Use soft, non-abrasive cloths for cleaning.

Cool and Dry Conditions:Store or use the fabric in cool, dry conditions. Excessive heat or humidity can affect the lamination and may lead to issues such as peeling.

Preventative Measures:

Use Furniture Protectors:Place furniture protectors or covers on items upholstered with printed emboss lamination velvet fabric. This helps prevent wear, scratches, and stains.

Professional Cleaning:For more extensive cleaning, consider professional upholstery cleaning services. Professionals have the expertise to clean and maintain the fabric without causing damage.

Environmental Considerations:

Protect from Moisture:Avoid exposing the fabric to excessive moisture or damp conditions. Moisture can affect both the velvet and the lamination, leading to issues like mold or deterioration.

Ventilate the Area:Ensure proper ventilation in the room where the fabric is used or stored. Good air circulation helps prevent the buildup of odors or mold.

Language

Language  English

English 中文简体

中文简体 عربى

عربى