Can you explain the manufacturing process of jacquard fleece and how it differs from other types of fleece?

The manufacturing process of

jacquard fleece fabric involves several steps to create a fabric with a distinctive pattern and texture. Jacquard refers to a type of loom or weaving technique that allows for intricate and complex patterns to be woven into the fabric. Here's an overview of the manufacturing process of jacquard fleece and how it differs from other types of fleece:

1. Fiber Selection:

Common Fibers: The process begins with the selection of suitable fibers. Fleece fabrics, including jacquard fleece, are often made from synthetic fibers such as polyester or a blend of natural and synthetic fibers.

2. Carding and Blending:

Carding: The fibers go through a carding process where they are combed to align the fibers in a parallel direction. This process helps create a smooth and consistent yarn.

Blending: Different colored or textured fibers may be blended at this stage if a multicolored or textured effect is desired.

3. Spinning:

Yarn Formation: The carded and blended fibers are spun into yarn. The spinning process determines the thickness and strength of the yarn.

4. Dyeing:

Coloring the Yarn: The yarn is dyed to achieve the desired color or pattern. In the case of jacquard fleece, the dyeing process is crucial as it determines the base color and serves as the foundation for the intricate jacquard pattern.

5. Jacquard Weaving:

Jacquard Looms: The jacquard weaving technique uses special looms equipped with a Jacquard head. This head contains a system of punched cards or a computerized mechanism that controls the lifting of individual warp threads.

Pattern Formation: The Jacquard loom allows for the precise control of each warp thread, enabling the creation of complex patterns and designs in the fabric. This is how the characteristic jacquard pattern is formed.

6. Fleece Fabric Formation:

Knitting or Weaving: The jacquard-patterned yarn is then used in either a knitting or weaving process to create the fleece fabric. Fleece is typically knitted, but the specific manufacturing method can vary.

7. Brushing and Napping:

Softening Process: After the initial fabric is formed, it undergoes a brushing or napping process. This involves raising the fibers to the surface, creating the soft and fuzzy texture that is characteristic of fleece.

8. Finishing:

Stabilization and Treatment: The fabric may undergo additional finishing processes for stabilization and treatment. This can include anti-pilling treatments, moisture-wicking finishes, or other enhancements depending on the desired properties of the final product.

9. Cutting and Sewing:

Fabric Panels: The finished jacquard fleece fabric is cut into panels or pieces based on the intended use.

Sewing: These panels are then sewn together to create various products such as blankets, clothing, or accessories.

Differences from Other Fleece Types:

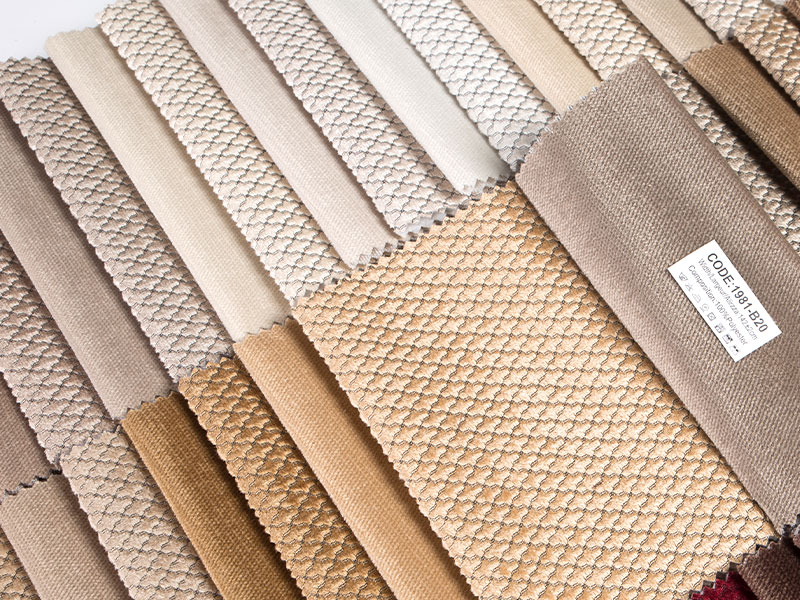

Jacquard Pattern: The key distinguishing feature of jacquard fleece is the intricate pattern created using the Jacquard weaving technique. This allows for highly detailed and complex designs that set it apart from simpler patterns in regular fleece.

Texture and Appearance: While regular fleece is known for its softness and warmth, jacquard fleece adds a decorative element with its patterned design. The combination of the jacquard pattern and the soft fleece texture creates a visually appealing fabric.

Manufacturing Precision: The use of Jacquard looms introduces a level of precision in pattern creation that may not be achievable with other types of fleece manufacturing methods.

How is the jacquard pattern incorporated into fleece fabric, and what distinguishes jacquard fleece from regular fleece in terms of design?

The jacquard pattern is incorporated into fleece fabric through a specialized weaving technique that allows for intricate and detailed designs. The key distinguishing feature of jacquard fleece lies in the complex patterns created using Jacquard looms. Here's how the jacquard pattern is incorporated into fleece fabric, and what distinguishes

jacquard fleece fabric from regular fleece in terms of design:

Jacquard Weaving Process:

Jacquard Looms:

Jacquard looms are special looms equipped with a Jacquard head, which contains a system of punched cards or a computerized mechanism. This mechanism allows for precise control over each individual warp thread.

Pattern Design:

The pattern design for jacquard fleece is created in a digital format. The design can be intricate, detailed, and multicolored.

Punched Cards or Computer Control:

In traditional Jacquard looms, punched cards are used to control the lifting of individual warp threads. Each card corresponds to a specific row of the design. In modern Jacquard looms, computerized systems are employed for greater flexibility and complexity.

Lifting Mechanism:

The Jacquard loom's lifting mechanism selectively raises or lowers the warp threads based on the instructions from the punched cards or computer program. This precise control allows for the creation of complex patterns and designs.

Shuttle Movement:

As the shuttle moves across the loom, it passes through the open spaces created by the lifted or lowered warp threads. The weft (horizontal threads) is interlaced with the raised and lowered warp threads, forming the jacquard pattern.

Pattern Repeats:

The design is repeated across the width of the fabric, creating a seamless pattern. The repetition of the pattern may vary based on the design and loom settings.

Distinguishing Features of Jacquard Fleece Design:

Intricate Patterns:

Jacquard fleece is known for its intricate and detailed patterns. These patterns can include florals, geometric shapes, textures, or even pictorial designs.

Multicolored Designs:

Jacquard fleece often features multicolored designs where different yarns or threads are used to create a visually rich and textured appearance. This allows for a wide range of color combinations within a single design.

Three-Dimensional Effect:

The precise control over warp threads in the Jacquard loom can create a three-dimensional effect in the design. This adds depth and visual interest to the fabric.

Customization:

Jacquard fleece allows for a high degree of customization in design. Manufacturers can create unique patterns, and the flexibility of the Jacquard loom enables the production of custom designs for specific purposes.

Variety of Motifs:

The jacquard technique enables the incorporation of various motifs, allowing for versatility in design. Motifs can range from classic and traditional to modern and contemporary.

Distinctive Aesthetic:

The combination of the jacquard pattern with the soft and fuzzy texture of fleece creates a distinctive aesthetic. It adds a decorative and luxurious element to the fabric.

Design Precision:

The Jacquard loom's precision in lifting individual warp threads contributes to the sharpness and clarity of the design. This level of detail sets jacquard fleece apart from regular fleece with simpler patterns.

In summary, the incorporation of the jacquard pattern into fleece fabric involves the use of specialized looms that offer precise control over the weaving process. The resulting jacquard fleece distinguishes itself through intricate and multicolored designs, creating a fabric with a unique and visually appealing aesthetic.

Language

Language  English

English 中文简体

中文简体 عربى

عربى