What materials are commonly used in blackout waterproof coated fabric?

Blackout waterproof coated fabrics are designed to provide both light-blocking (blackout) and water-resistant or waterproof properties. The choice of materials plays a crucial role in achieving these features. Here are the common materials used in blackout waterproof coated fabric:

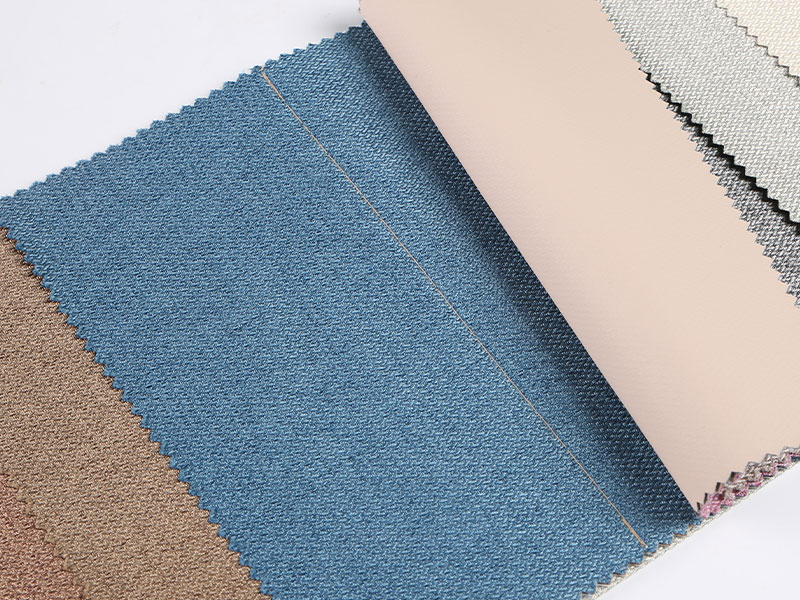

Base Fabric:

Polyester: Polyester is a popular choice for the base fabric due to its durability, resistance to wrinkles, and affordability. It provides a stable foundation for the coating and contributes to the fabric's overall strength.

Blackout Coating:

Acrylic Foam or Foam Backing: Many blackout fabrics feature an acrylic foam or foam backing. This foam layer not only enhances the blackout effect by blocking light but also provides insulation and sound absorption. It adds thickness and weight to the fabric.

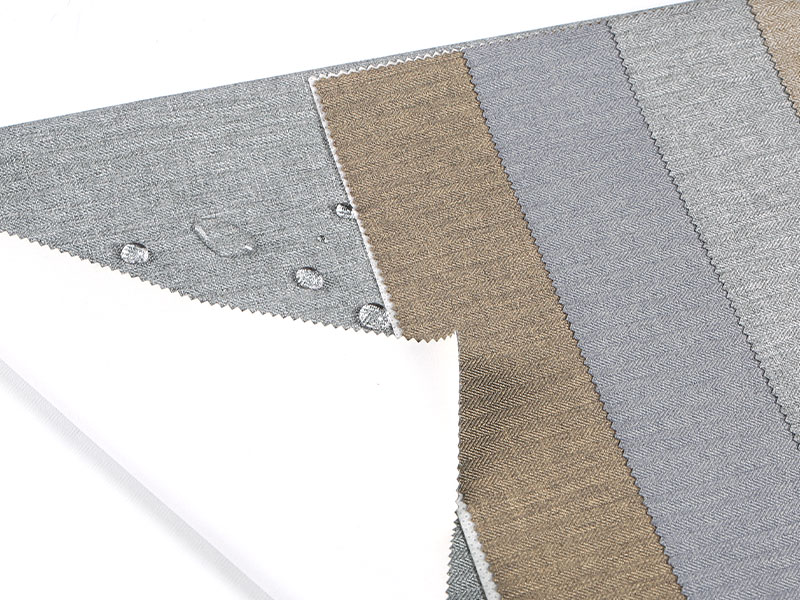

Waterproof Coating:

Polyurethane (PU) Coating: PU coating is commonly used for providing waterproofing to fabrics. It forms a protective layer on the surface, preventing water penetration while maintaining flexibility.

Polyvinyl Chloride (PVC) Coating: PVC coatings are also used for waterproofing. They create a durable and water-resistant layer, making the fabric suitable for outdoor applications.

Fluorocarbon Coating (e.g., Teflon): Fluorocarbon coatings provide water repellency and stain resistance. These coatings are often used in combination with other materials for added protection.

Lining (Optional):

Thermal Lining: Some blackout waterproof coated fabrics may have a thermal lining, often made of materials like acrylic, to enhance insulation properties and regulate temperature.

Microfiber or Polyester Lining: For added durability and smoothness on the reverse side, microfiber or polyester linings may be used.

Face Fabric (Optional):

Cotton or Polyester Face Fabric: In some cases, a layer of cotton or polyester may be added to the face of the fabric for a softer touch and more varied aesthetic options.

These materials are selected for their specific properties, and their combination determines the overall performance of the blackout waterproof coated fabric. The choice of materials is influenced by factors such as the intended use of the fabric, the desired level of blackout, and the environmental conditions it will face (e.g., exposure to rain or sunlight).

It's important to note that while these materials contribute to blackout and waterproofing, the effectiveness of the fabric depends not only on the materials but also on the manufacturing processes and the quality of the coatings applied. Additionally, advancements in textile technology may lead to the incorporation of new materials or improved formulations in blackout waterproof coated fabrics.

What additional features, such as UV resistance or antimicrobial properties, are commonly found in blackout waterproof coated fabric?

In addition to blackout and waterproof properties,

blackout waterproof coated fabrics may be enhanced with additional features to improve their overall performance and functionality. Some common additional features include:

UV Resistance:

Purpose: Protects the fabric from the harmful effects of ultraviolet (UV) radiation, which can cause fading and deterioration.

Benefit: Extends the lifespan of the fabric and helps maintain its color and appearance, especially in outdoor applications.

Antimicrobial Treatment:

Purpose: Inhibits the growth of microorganisms, such as bacteria and mold, on the fabric's surface.

Benefit: Reduces the risk of odors, stains, and deterioration caused by microbial activity, making the fabric more hygienic and durable.

Stain Resistance:

Purpose: Creates a protective barrier against stains, making it easier to clean and maintain the fabric.

Benefit: Improves the fabric's resistance to spills and stains, enhancing its appearance and longevity.

Fire Retardancy:

Purpose: Delays or inhibits the spread of flames in the presence of a fire.

Benefit: Adds a layer of safety, making the fabric suitable for applications where fire safety is a concern.

Anti-Wrinkle Treatment:

Purpose: Reduces the tendency of the fabric to wrinkle, ensuring a smoother appearance.

Benefit: Minimizes the need for ironing or pressing, maintaining a neat and crisp look.

Static Resistance:

Purpose: Prevents the build-up of static electricity on the fabric.

Benefit: Reduces the attraction of dust and lint, contributing to a cleaner and more comfortable environment.

Mildew Resistance:

Purpose: Inhibits the growth of mildew, which is a type of mold that can thrive in damp conditions.

Benefit: Prevents the development of mildew spots and maintains the fabric's cleanliness, especially in humid environments.

Thermal Insulation:

Purpose: Enhances the fabric's ability to provide insulation against heat or cold.

Benefit: Improves energy efficiency by helping to regulate temperature, making the fabric suitable for curtains or window coverings.

Breathability:

Purpose: Allows air circulation through the fabric.

Benefit: Enhances comfort, especially in applications where breathability is essential, such as clothing or bedding.

Water Repellency:

Purpose: Adds an additional layer of water resistance to the fabric's surface.

Benefit: Helps water bead and roll off the fabric, preventing saturation and enhancing overall waterproofing.

These additional features are often incorporated into blackout waterproof coated fabrics to meet specific performance requirements and address the needs of various applications. Depending on the intended use, consumers can choose fabrics with the combination of features that best align with their preferences and functional requirements.

Language

Language  English

English 中文简体

中文简体 عربى

عربى